[ad_1]

We could earn income from the merchandise obtainable on this web page and take part in affiliate applications. Study Extra ›

Figuring out the very best reloading press is tougher than you would possibly suppose. First off, individuals reload for various causes and have totally different expectations. What fits the informal reloader who desires to craft a pair dozen rounds for a deer rifle annually is worlds aside from the wants of the hardcore handgunner who’s making an attempt to get in hundreds of set off pulls in essentially the most economical method attainable. Even within the narrower realm of reloading for precision rifle you could have divergent objectives — and specialised tools to match. The best way a benchrest shooter reloads is vastly totally different from how somebody like me who shoots ELR and sensible discipline “sniper” type matches makes precision rifle ammo.

So, you may perceive why the reply to what’s the very best reloading press is: It relies upon. A part of what additionally determines the very best reloading press for somebody is their price range and technical savvy, along with their particular ammunition necessities.

Models within the Greatest Reloading Press Take a look at

How I Examined the Greatest Reloading Presses

For this take a look at I targeted on metallic centerfire reloading for handguns and rifles. We’ll cowl the gamut of the very best reloading presses for shotgunners at one other time. (Although if you wish to have a look at a drool-worthy setup for shotgunning, try this evaluate of the Dillon SL 900.)

To check these presses I, after all, did a bunch of reloading with them. The largest line of demarcation on this evaluate was between these models I’ve years (and generally a long time) of expertise with, and people which can be new to me.

To maintain the take a look at manageable, I restricted the variety of presses I included. The reality is that there aren’t many reloading presses that flat-out stink. Any press that’s endured for a very long time (hey, Rock Chucker) you should buy with a excessive diploma of confidence.

When it comes to my particular protocol, I put every press via a gamut of makes use of. I loaded centerfire rifle cartridges in several courses based mostly on case size. Within the “quick” class that included .223 Rem. and 6mm GT, for medium-length cartridges I did 6.5 Creedmoor and .308 Win., and within the longer class I did 6.5 PRC, .300 PRC, and .300 Norma Magazine. For handgun ammunition I caught with loading 9mm.

I resized and decapped brass; primed the brass; seated bullets; and, in some instances, carried out further processes with neck mandrels, expander dies, and the like.

Single-Stage Versus Progressive Reloading Presses

I’ve included each on this roundup, particularly since I personally gravitate towards progressive reloading presses for his or her skill to crank out numerous ammo. That stated, in case you’re new to the reloading recreation, a progressive press is just not the way in which to go. Even for knowledgeable reloaders they’re difficult and infrequently irritating.

Among the many finest recommendation I received after I began reloading was to maintain it easy and simply give attention to making good ammunition. Don’t fear about quantity. Don’t give attention to superior methods. Merely keep on with the fundamentals and craft good ammo. And for that, a single-stage press is your pal. A fantastic useful resource for somebody beginning out is that this evaluate of the finest reloading kits.

Greatest Reloading Presses: Evaluations & Suggestions

Greatest for Excessive-Quantity Precision: Forster Co-Ax

Key Options

- Fast change dies

- Sturdy building

- Quick operation

- Contains spent primer catch system

- Makes use of Forster lock-rings to safe dies

- Ambidextrous operation

- Common shell holder

- Floating shell holder self-centers brass with the die

Execs

- Quick, clean, and simple to run

- Exact resizing

- Small footprint

- Dependable

Cons

- Excessive demand means you would possibly must backorder one

If I attempted to let you know what number of rounds I’ve loaded on my Forster Co-Ax I’d be guessing — however it’s many, many hundreds. I’ve run one for almost twenty years and it’s my go-to press for resizing precision rifle brass.

At first blush you wouldn’t suppose this press able to resizing brass as exactly because it does. There’s a good bit of slop and play within the design. The linkages rattle a bit. The slot that holds the dies induces some wiggle. And in lieu of a conventional shell holder, the press has common jaws that slide in and pinch the bottom of the case because it travels up and into the die — yet one more shifting half.

However all that slop — although I hesitate to make use of that phrase as a result of it feels like a unfavorable — is intentional and helps the press self-align persistently with every stroke of the deal with. (In truth, the time period Co-Ax refers back to the co-axial design of the press and the connection between how the die is held on one finish and the way the brass is held on the opposite.)

When resizing and bumping the shoulders of my 6 GT brass, for example, about 80 p.c of the brass measures the identical to the thousandth, whereas 15 p.c could be .001 inches out, plus or minus. The remaining 5 p.c isn’t greater than .002 inches out. That’s nice consistency, even for ELR work.

Different single-stage reloading presses are able to related consistency, however the place the Forster Co-Ax actually shines is with its pace.

The shell holder’s pinching jaws seize the rim of the case and middle the brass for you that means you don’t need to information the case right into a slender slot the way in which it’s important to on different presses. Likewise, once you decrease the press the jaws let go of the brass making it simple to seize and swap in a brand new piece. This alone saves many seconds per cycle.

Like many followers of the Forster, I’ve a bin of brass that wants resizing on one facet of the press and an empty receptacle on the opposite. When you get into the move, the decapping and resizing goes shortly.

The mechanical benefit of the press is outstanding too — and this additionally contributes to the system’s pace. The stroke to actuate the press is compact however almost easy. Even when resizing bigger cartridges, just like the .300 Win. Magazine. or 300 PRC, the Co-Ax doesn’t must be muscled.

Swapping dies is one other space the place the Co-Ax is blazing quick. The lock ring on the die — Forster makes their very own — slips into the slot on the entrance of the press and is retained by a easy set screw. With a little bit of follow, you turn dies in seconds.

Organising the dies for proper shoulder bump takes a little bit of fiddling and expertise to get proper. In contrast to conventional presses you don’t backside out the Co-Ax on a shell holder to determine a baseline.

Spent primers drop via a tube into a transparent plastic jar. The jar is a bit fragile, so that you would possibly find yourself changing it sooner or later, and it’s the solely component of the press I’d think about weak.

The press additionally primes brass although it’s a little awkward and never a perform I personally use.

However total this fabulous machine is quick, exact, intuitive and simple to run, and an awesome worth as a long-term and dependable funding.

Most Versatile: Redding T-7 Turret

Key Options

- Interchangeable seven-station turret heads

- Rotates between stations shortly

- Forged-iron building

- Greater than 3.8 inches of ram journey

- Could be outfitted with an automated priming system

- Shell holders may be rotated to desired orientation

Execs

- Extraordinarily handy

- Resizes exactly

- Could be run shortly

- Quick toggling between stations

Cons

That is one other press that’s been a mainstay of my reloading room for many years. As for a lot of reloaders, the Redding T-7 was the primary premium press I bought. The great thing about this press is its pace and precision. No different mainstream press is its equal on this regard.

The rotating turret on high allows you to mount as much as seven dies — sufficient for 2 or three totally different cartridges, or for including specialised dies to carry out specialised operations in your brass.

As an illustration, I’ll usually place a resizing die in a single station however take away the expander button from the decapping rod. Within the station subsequent to it I’ll place a neck expander die. I’ll resized and decap the brass with one cycle of the press, then rotate the turret to the following die and dimension the within of the neck with the following cycle. I can carry out each operations in the identical time it takes to learn this sentence.

(The rationale for doing that’s as a result of I’m usually not a fan of pulling the expander ball up via the brass — it could actually pull the shoulder up, messing together with your shoulder bump and head house. I’d quite use a devoted carbide expander mandrel to dimension the within of the neck on the downstroke, as a result of it gives higher management over neck constriction and yields extra constant outcomes.)

That’s only one instance of how you should use the T-7. For reloading handgun ammunition the rotating turret allows you to resize, prime, and bell the case neck shortly, after which after including powder the seating and crimping may be carried out in a break up second.

One factor to learn about this press is that with any resizing operation you need strong contact between the shell holder and sizing die. It’s vital that you just get an excellent cam-over once you decrease the deal with to the underside of the stroke. That’s as a result of the turret head is designed to tilt ever so barely to get sq. to the shell holder.

What this implies is that to manage your shoulder bump you don’t wish to again the sizing die off, as is typically really useful. As an alternative, get the suitable Competiton Shellholder Set from Redding to exactly set the shoulder bump.

I haven’t used the press’s automated priming characteristic in years. I usually prime my brass with both the Primal Proper CPS, or the RCBS Computerized Priming Software that I’ve augmented with Holland’s wonderful Excellent Primer Seater adapter unit. Each these permit for quick priming whereas controlling primer seating depth. That stated, the priming system on the Redding T-7 is greater than satisfactory.

New this yr is a software head that may accommodate Redding’s 1-inch dies, which they only launched. I’ve solely run just a few items of brass via my 6.5 PRC die however I just like the outcomes I’ve seen to date.

The larger-diameter dies present extra assist, and are stronger than, conventional 7/8-inch dies and due to this fact ought to ship higher outcomes. But one more reason to contemplate this press.

Greatest Excessive-Finish Reloading Press: Space 419 Zero

Key Options

- Interchangeable turret heads settle for 7/8- and 1-1/4-inch dies

- Turret can shortly rotate to go from one die to a different

- Turret heads have both eight or 9 stations

- Deal with adjusts for size and may be connected to both facet of press

- Press opening is 4.75 inches with 4.4 inches of ram journey

- Inside contained spent primer catch system

Execs

- Straightforward to make use of

- Holds extraordinarily tight tolerances

- Wonderful ergonomics

- Nice workmanship

Cons

- Costly

- Resizing is finest completed with Space 419’s M-Collection dies

How excited have been precision rifle nerds for the arrival of the Space 419 Zero press? Think about an enviornment stuffed with seventh grade ladies when Taylor Swift walks on stage and also you’ll get the concept.

The Space 419 Zero is a beautiful piece of labor, each to have a look at and to function. It exudes high quality and precision, so it’s little marvel that it produces wonderful outcomes.

I’ve been utilizing one since they have been launched, principally for crafting ELR competitors hundreds. Most of my lever pulls have been with the .300 Norma Magazine. and .300 PRC.

With out getting too deep into the weeds, let me say that the Zero Press is the very best press I’ve ever used. It’s so clean, provides such nice suggestions, and is so constant that I can’t think about anybody who will get one not being glad with the outcomes.

There may be one caveat I would like to incorporate although. I had points resizing brass with customary 7/8-inch dies with the press. After I ran the ram, it might are inclined to bind up and stick. However for bullet seating, operating neck mandrels and different processes it was good.

Happily, Space 419 has a repair for this. It’s their M-Collection sizing die, which is a part of the Zero Press ecosystem, and is a murals. It’s a 1 1/4-inch sizing die that has a micrometer adjustment on high to exactly management shoulder bump. (New Zero Presses ship with the 8-station turret that features 4 1 1/4-inch and 4 7/8-inch die places. You too can get a nine-station turret for simply 7/8-inch dies.)

The primary time I attempted the M-Collection dies I used to be blown away. They’re really easy to make use of and work so effectively that it nearly looks like dishonest. The lineup of M-Collection dies is rising, however nonetheless considerably restricted. Chances are high, nonetheless, if the Zero press appeals to you that the cartridges you shoot are on the record.

Right here’s the opposite factor: Like tickets to see T-Swift, shopping for a Zero press and M-series dies is a spendy proposition. There’s no getting round the truth that it’s a important funding. But when creating exact handloads on your rifle is a precedence I doubt you’d remorse it.

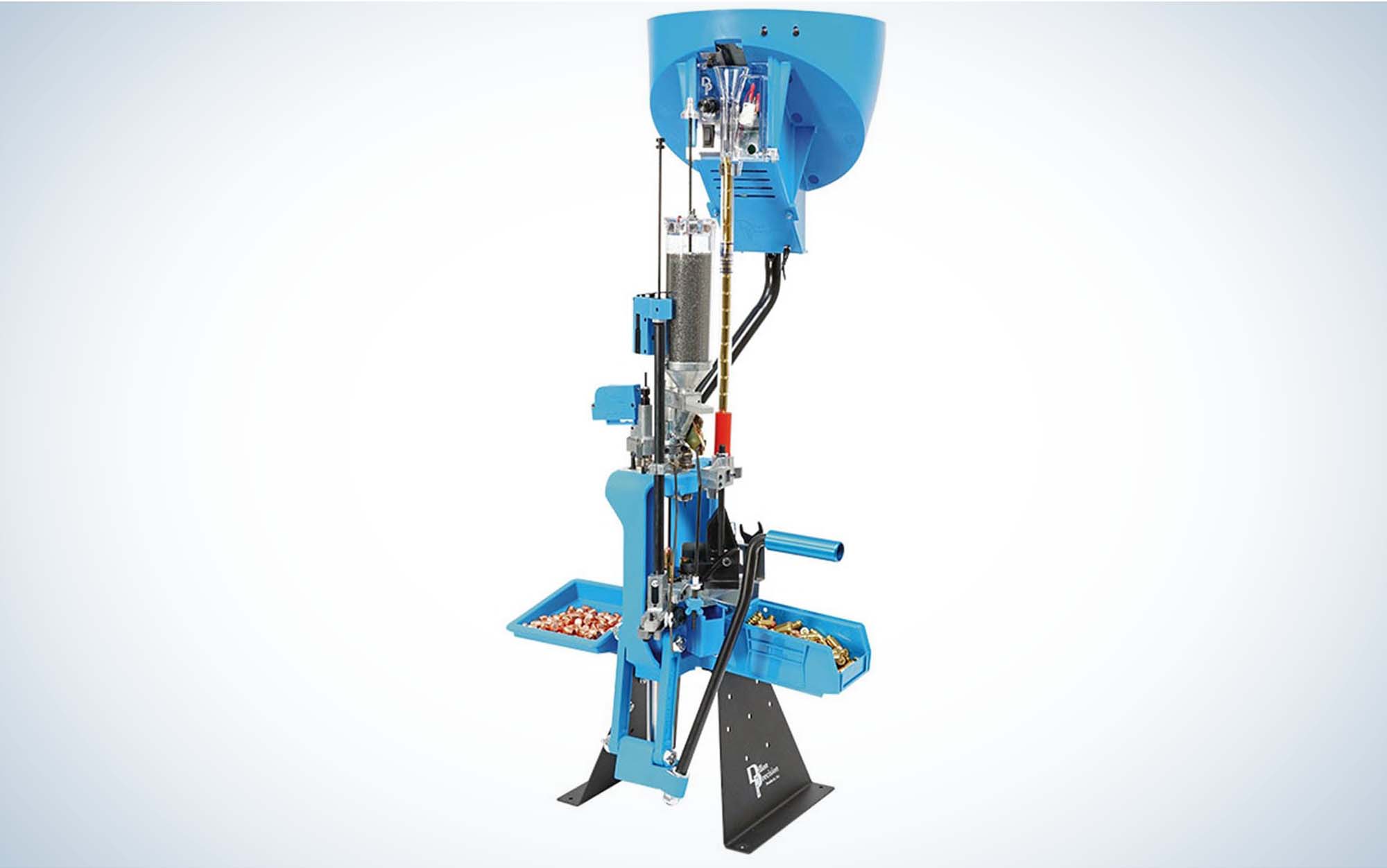

Greatest for Excessive Quantity Reloading (tie): Dillon XL750

Key Options

- Excessive working pace

- 5-station software heads may be swapped

- Can accommodate a variety of calibers

- Improved primer feeding in comparison with Dillon XL650

- Straightforward to improve and customise with Dillon equipment

- Many aftermarket equipment obtainable as effectively

Execs

- Easy, dependable operation

- Could be tailored to load precision rifle ammunition

- Wonderful buyer assist

Cons

Dillon is the foremost producer of progressive presses and has many choices of their lineup. The Dillon XL750 is one in every of their latest presses and changed their well-known XL650. The machines are related in lots of respects, however the XL750 was created partly to handle considerations in regards to the XL650’s priming system.

I’ve received each machines and have loaded hundreds of rounds of ammunition on my XL650, principally for precision rifle competitions. At the moment, my XL750 is about up for .223 Rem. to make coaching ammunition for precision rifle.

It does an awesome job in that capability. The automated case feeder, which I extremely advocate, is principally bomb proof, and the whole lot else on it really works like a appeal. Principally, I’m operating new brass via mine, hitting the necks with an expander mandrel to clean them out. I’m additionally utilizing the unit to prime the brass, which it does through the ahead push on the deal with.

You’ve two routes to comply with by way of meting out powder. You may both use the included volumetric powder measure or go together with a high-speed powder dispenser arrange subsequent to the machine, just like the RCBS Matchmaster.

The Matchmaster is clearly slower, however extra exact, letting you management your powder costs to plus-or-minus a single kernel of powder. The included measure is way quicker, not as correct, however nonetheless does an awesome job serving to you craft high quality ammunition.

The bottom worth of the XL750 is $739 bucks, however you may trick it out with plenty of add-ons to enhance efficiency. The Casefeeder provides $300 to the unit and might be the commonest (and helpful) improve. The Powdercheck, for one more $100, could be a sensible choice too, notably in case you’re cranking out handgun ammo.

Greatest for Excessive Quantity Reloading (tie): Mark 7 Apex 10

Key Options

- Ten-stage software head

- Excessive-quality machining on one-piece body

- Shell plate indexing, priming system, and volumetric powder measure all capable of be fine-tuned

- Could be upgraded to totally automated ammunition manufacturing

- Comes with case feeder

- Contains {hardware} to transform between massive and small primers

Execs

- Wonderful workmanship and design

- Extraordinarily clean and ergonomic to function

- Ten-station software head supplies tons of flexibility

- Excellent technical assist

Cons

- Costly

- Not splendid for learners

The Apex 10 is the entry-level mannequin press within the Mark 7 lineup however make no mistake — this isn’t a press for first-time reloaders. This 10-stage progressive press is a robust and well-designed machine that may sustain with no matter quantity of taking pictures you have interaction in, however it requires a good bit of reloading expertise to arrange and tune.

The comfortable place for this press is churning out tons of (and even hundreds) of rounds of pistol ammo an hour, however it may be used (as mine is) to make prime quality rifle ammunition too.

I’ve received mine set as much as make 6.5 Creedmoor ammo, which I shoot by the pallet annually. I’m making rounds with new and once-fired brass and the Apex 10 does an awesome job with each.

Working the machine is a pleasure. The Apex 10 is machined like a Swiss watch. Every pull of the deal with is clean and offers nice tactile suggestions. It additionally supplies loads of mechanical benefit in order that having the press carry out quite a lot of operations without delay isn’t fatiguing.

The included case feeder works flawlessly and feeds brass to the primary station completely every time. From there the brass progress as follows: a sizing and decapping die; neck mandrel; primer station; powder measure; bullet seater; and into the bin on the entrance of the machine the place it lands with a satisfying “plop.” In some unspecified time in the future I’d like so as to add an automated bullet feeder to make it run even quicker.

When getting mine arrange I managed to get a primer caught below the shell plate. I took the machine aside to clear the mishap, after which contacted their technical assist as a result of the shell plate wasn’t indexing fairly proper afterwards.

The tech I spoke with, Jacen Hinkson, was terribly useful and affected person. He not solely helped repair the difficulty, which was minor, but additionally gave me nice perception into the workings of the machine. Know that a part of what you pay for once you buy a sophisticated press is the corporate’s technical assist.

The $2,500 base worth places the Apex 10 out of attain for a lot of reloaders — and relying on how far you wish to go accessorizing it the ultimate determine may be double or triple that quantity — however this unit is only a step under a commercial-grade ammunition maker.

For the reloader whose taking pictures necessities, price range, and need for high quality match up with the Apex 10, it’s a terrific selection.

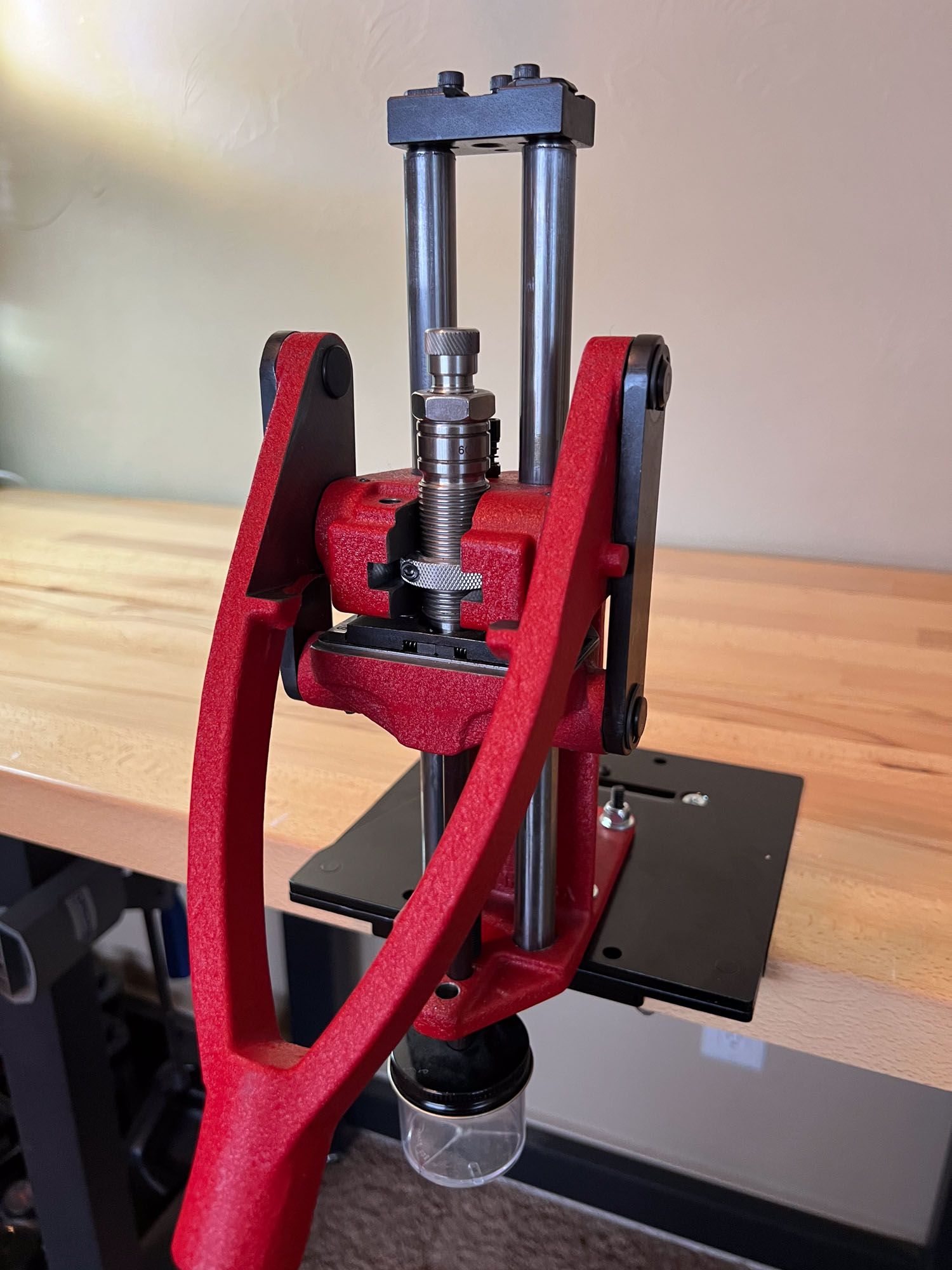

Greatest Reloading Press On a Price range: RCBS Summit

Key Options

- Outsized 2-inch metal ram

- Forged iron body and metal linkage

- Compact footprint

- Open design supplies ample entry

Execs

- Economical

- Straightforward to make use of

- Dependable

Cons

- Primer catch bin not very rugged

- Doesn’t prime brass

This fundamental single-stage press supplies a ton of high quality for the worth. It doesn’t have the bells and whistles related to progressive- and turret-style presses — however it doesn’t have their shortcomings both.

This is a perfect press for somebody entering into reloading. It can allow you to construct your abilities and make some rattling high quality ammo on your rifle or handgun within the course of. And the reality is that regardless of how skilled and specialised you get together with your reloading, you’ll by no means remorse having an excellent single-stage press in your bench.

The Summit is so simple as it will get. The iron body has two cutouts for bolts to mount it to your work floor. The lengthy deal with may be screwed into both facet of the press for ambidextrous operation. And that’s all there’s to getting the Summit up and operating, aside from attaching the primer catch bin with its two fasteners.

The press works by decreasing the die onto the brass. The platform the die screws into slides alongside the 2-inch diameter metal pillar that types the spine of the Summit. This leaves the entrance of the press extensive open, making for a handy work space.

When absolutely raised the press has 4.5 inches of clearance so it could actually accommodate longer cartridges with ease.

The deal with that comes with the press is lengthy and supplies numerous leverage when resizing. However its size makes it a contact awkward. RCBS sells a shorter deal with for $18 that may work higher (and be extra handy) when seating bullets, particularly in any quantity.

The press features a Zerk becoming (a grease nipple) that permits you to preserve it correctly lubricated for years of use.

Greatest Price range Co-Axial Press: Frankford Arsenal M-Press Coaxial

Key Options

- Floating common shell holder

- Can load the whole lot from small pistol to massive magnum cartridges

- Fast change die system

- Contains three floating die blocks

- Doesn’t overhang the bench

- Built-in LED mild

- Ambidextrous operation

- Sells for $249

Execs

- Wonderful worth

- Straightforward to make use of

- Neatly designed

Cons

- Doesn’t all the time ship the very best mechanical benefit

I used to be extremely inquisitive about this press earlier than I received it. Given my longstanding and unapologetic affection for the Forster Co-Ax, I puzzled whether or not this relative newcomer (it was launched about 5 years in the past) may discover a place in my coronary heart.

The reply is sure. Just like the Forster, the M-Press is a co-axial press, that means it’s designed in order that the floating die and the floating shell holder self-align for repeatable outcomes. However there’s a lot that’s totally different between the presses, together with some parts the place the Frankfort M-Press has the sting.

The headline is that this can be a stout, easy-to-use, press that comes with some intelligent and helpful options. As an illustration, it has an integral tray that captures spent primers that tucks in out of the way in which beneath the shell-holder system. And the shell holder system adjusts simply for various dimension case heads by merely rotating every jaw via the 4 choices (massive, small, .223, and .308).

The LED mild on the high of the press illuminates the workspace and runs off a micro-USB cable, so you can plug it into an exterior battery supply if a wall socket isn’t obtainable.

The press additionally comes with three floating die blocks and a handy storage field to carry them with dies in place. The floating die blocks, that are secured within the body by a ball-bearing detent, snap into place and out in a flash.

One other fascinating characteristic of this press is the flexibility to vary the motion of the press from cam-over to a constructive cease. You make the change by flipping the linkages, which takes only a couple minutes to do.

I resized plenty of once-fired 6.5 Creed brass within the press. The press delivered good mechanical benefit on the downstroke, however I discovered when utilizing the ball expander within the full-length sizing die that it caught a bit greater than I might anticipate. I adjusted my method to “pop” the deal with on the upstroke and that handled the difficulty.

It didn’t ship the identical dead-nuts consistency because the Forster, however it was nonetheless good. I wouldn’t hesitate to make use of it to make ammo for my searching rifle, or follow ammo for my competitors rigs. After I switched to the seater die, the press ran completely clean and was splendidly constant.

One factor you may’t argue about is the worth. At $250 it’s a screaming worth with plenty of nice options.

Notes About Progressive Reloading

There’s a robust line of demarcation between single-stage and progressive reloading that must be revered. I touched on this above. Progressive presses usually aren’t an awesome selection for first timers. That stated, in case you’re able to make the leap don’t let the complexity maintain you again. Listed below are some pointers for once you do.

Take It Gradual

When establishing a progressive press don’t hurry. Give your self loads of time and don’t essentially attempt to do it suddenly. I do know this would possibly sound overly cautious however belief me — it’s going to prevent hassles downstream.

All of the bits and items of a progressive press must work in concord, and in case you overlook one small element through the preliminary setup it’s going to chunk you on the tail later. Ensure that once you carve out time to arrange the press that you’re targeted and aren’t contending with different distractions.

Be Methodical

One other factor that may’t be over-emphasized when taking the plunge into the world of progressive presses is to take one step at a time when establishing the dies and stations. So get your sizing/decapping station found out earlier than including a bullet seater, primers, or powder drop.

Plan on sacrificing an excellent quantity of brass throughout this part as you are taking measurements and tune every die and station in flip.

Tech Assist Is Your Buddy

Like most guys I really feel that studying directions is an admission of defeat. After I began fooling with progressive reloaders I wanted to examine that perspective on the door. They’re advanced, intricate, and — critically — not intuitive.

So, deal with the directions as if they’re a deal you’re hanging with the satan. Take note of each element.

Past that, make the most of the corporate’s technical assist companies. I do know from private expertise that the assist employees at Mark 7 and Hornady are wonderful on this regard, and I wouldn’t hesitate to lean on them if I’m in any respect confused.

Be Delicate

This recommendation pertains to all reloading however is particularly the case with progressive presses. If one thing doesn’t really feel proper, cease. By no means pressure the press. Respecting that tactile suggestions is vital to keep away from making a foul spherical or presumably breaking one thing. If the press instantly feels totally different, take the time to determine it out.

Upkeep Is Essential

Lastly, take note of the rules regarding lubrication of the press and keep watch over the tightness of the totally different bolts and fasteners. You may get away with neglecting many single-stage presses (although you shouldn’t) however you may’t do this with a progressive press.

FAQs

A progressive reloading press is a machine that may carry out a number of processes with every pull of the deal with. A totally-equipped progressive press can resize and decap your brass, seat a primer, drop a powder cost, and seat a bullet with every cycle. As well as, a progressive press may be set as much as swage brass, bell the mouth of a pistol cartridge, crimp a bullet, and use sensors to let you know if one thing is amiss.

This is a superb query. And the reply is: generally. A number of right this moment’s manufacturing unit ammo is splendidly correct, and it may be tough for reloaders to enhance on that efficiency. Nevertheless, manufacturing unit ammo may be inconsistent. A specific batch of ammo that shot lights out prior to now may not carry out as effectively this time round since ammo makers usually substitute elements like powders and primers. Reloading permits you to keep consistency.

Additionally, in case you’re keen to spend money on elements geared particularly for accuracy and take the time to grasp them you may definitely enhance on even the very best manufacturing unit ammo.

The philosophical reply is your time. Reloading is one thing you find yourself devoting many hours to grasp. Talking extra virtually, powder and bullets may be costly. Powder particularly in case you load massive cartridges that require plenty of propellant. It’s one argument for reloading smaller varmint rounds. Your pound of powder in these pipsqueak cartridges goes additional.

When it comes to bullets, you get what you pay for. When you’re taking pictures high-level long-range competitors, operating premium bullets like Hornady A-Suggestions or Berger Goal Hybrids goes to set you again a bit. Happily, there are good bullets for these on a price range that may in all probability get the job carried out.

Broadly talking, the 2 forms of reloading presses are single-stage presses and progressive presses, which we’ve already coated at size. Beneath these umbrellas are different classes of press designs, like co-axial presses, O-frames, arbor presses, turret presses, automated indexing progressive presses, and guide progressive presses.

A single-stage reloading press is one which performs a single perform with every cycle of the deal with. The ram both raises the brass to the die (just like the Redding T-7) or lowers the die to the brass (RCBS Summit) relying on its design.

Usually talking, a single stage press can create hundreds which can be extra correct than a progressive press. That stated, progressive presses are frequently used to churn out ammo for long-range rifle competitions. Many high opponents in PRS-style competitions reload on progressives.

Reloading could be very protected so long as you are taking fundamental precautions. At all times put on security glasses (which is a great factor to do everytime you use instruments of any type) and preserve distractions to a minimal. It is usually a sensible behavior to take good notes. That may preserve you on observe and assist you keep away from mishaps.

Ultimate Ideas on the Greatest Reloading Presses

Whereas there’s no scarcity of fine presses on the market, the very best reloading press for you hinges in your expectations, price range, and experience.

When you’re new to reloading, keep on with the fundamentals. Put money into an excellent single-stage press and learn to use it. Or, when you’ve got extra money to spend, begin with a turret press just like the Redding T-7, which is principally a lifetime funding.

When you shoot a excessive quantity of rounds, whether or not pistol or rifle, you then’re going to wish to have a look at progressive presses, that are designed for that objective.

Now if you end up needing to make plenty of very exact ammo, you’ll possible find yourself utilizing a couple of press to fulfill your objectives whereas investing in plenty of costly (however hopefully time-saving) equipment.

In any case, this record of the very best reloading presses is an efficient place to begin (or proceed) the journey.

[ad_2]